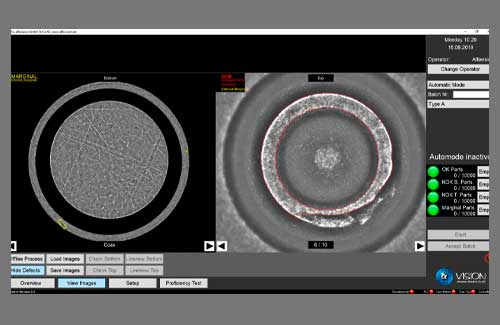

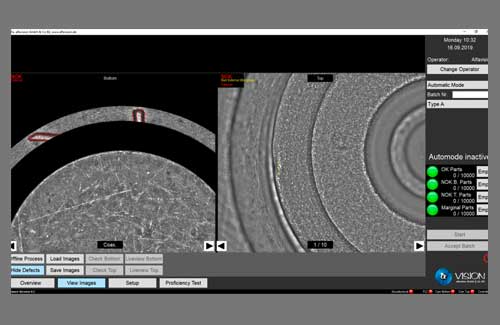

Surface inspection

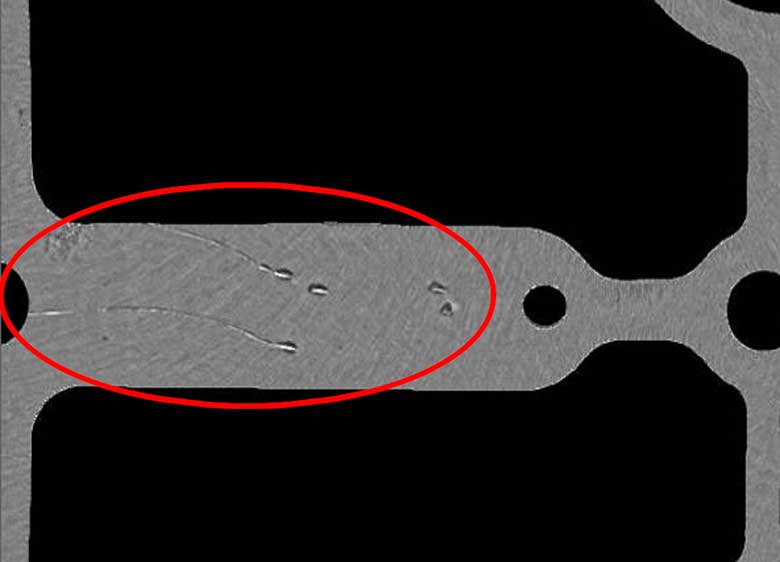

The procedures and techniques developed by alfavision for testing the quality of product and functional surfaces represent complete systems based on hardware and software.These surface inspection methods are used to check metal and plastic surfaces, coatings, paintwork and other finishes for scratches, dents, cavities, dirt, inclusions, bubbles and flaking. The physical resolution of such systems is up to 10 micrometers, using line or matrix camera technology. Both 2D and 3D structures can be captured with it.

The procedure for surface inspection allows the following areas of application:

- Analysis of local surface properties

- Comparison with optimal patterns

- Combination of analysis and comparison

- Can be combined with the testing and measurement of contours and shapes

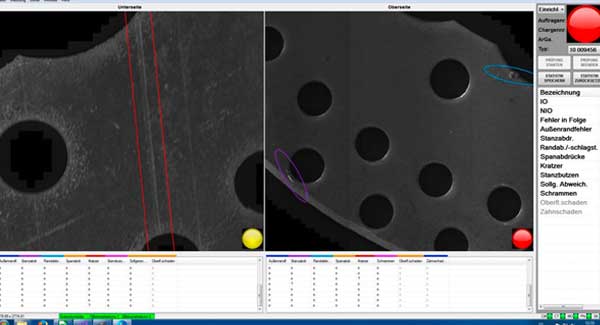

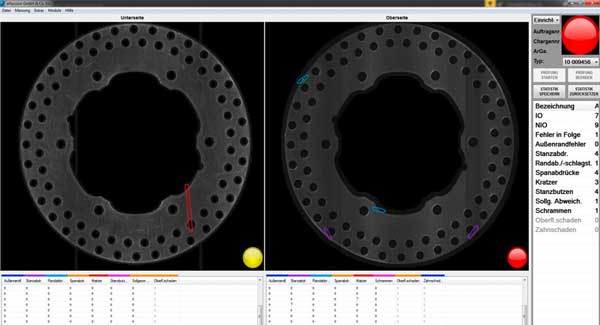

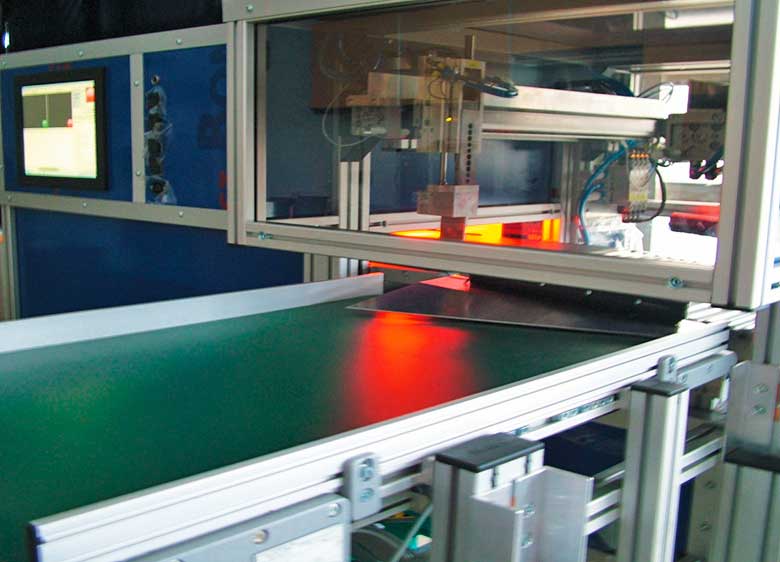

Surface control in the line

This complete system offers an automated 100% surface control in the production line. Components are checked on both sides. Microscopic defects such as scratches, dents, geometric deviations and damage are recognized.This technology for surface control in the line, developed by alfavision, replaces a manual control process, which can only be carried out with a high expenditure of personnel and time. For example, manual binocular testing of both sides of a component is no longer necessary. The fully automated surface inspection in the line, on the other hand, takes place within a few seconds per part. This also ensures a significant increase in the productivity of the production line.